Our BHL range delivers the maximum output at the lowest cost of operations per unit output.

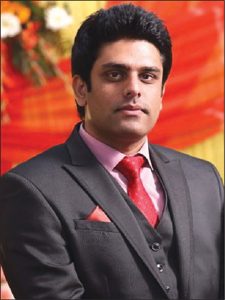

Yogesh Sindwani, DGM Backhoe Loader , Product Manager, Escorts Construction Equipment. Our focus for coming time will be on unexplored markets to increase our market penetration. Escorts is the first Indian company to have designed backhoe loaders indigenously.

Yogesh Sindwani,

Yogesh Sindwani,

DGM – Backhoe Loader ,

Product Manager,

Escorts Construction Equipment.

Our focus for coming time will be on unexplored markets to increase our market penetration.

Escorts is the first Indian company to have designed backhoe loaders indigenously. Its product development team has utilized extensive consumer insight and feedback to develop the product which is built to withstand India’s rough terrain and heavy usage. “Our BHL range offers the best package on the technical specifications and delivers the maximum output at the lowest cost of operations per unit output, says Yogesh Sindwani DGM – Backhoe Loader

Product Manager Escorts Construction Equipment Excerpts from the interview….

Could you tell us about the range offered in the backhoe space?

Escorts has two models in BHL product named as Digmax II and Jungli. Both variants come with 76 HP and 90 HP engine option. We have tested our BHL range for almost 20,000 hurs before launching in market. Escorts Digmax II is powered by reliable fuel efficient Kirloskar engine which comes in 2 options of 76 HP and 90 HP. Digmax II is also available with 2WD and 4WD options.

Escorts Jungli – Escorts has taken its learning from tractor engines, to build the most fuel efficient, compact, brute power engine for Jungli machine which consumes less fuel compared to other BHL machines in India. Machine has unique features which includes heady duty boom, heavy duty loader arm, hard strata bucket. It is powered by 76 HP Escorts Engine along with2WD and 4WD options.

Escorts Jungli with 2WD option is named as Escorts Jungli XT; XT stands for extra wherein we offer 2 year / 4000 hours warranty (whichever is earlier) as standard along with 2 years’ consumable parts kit. These extra offerings make Jungli XT more reliable machine for end user.

Escorts Jungli with 4WD option is named as Escorts Jungli 4X4.

What are the unique features of your range of backhoe?

Our BHL range offers the best package on the technical specifications and delivers the maximum output at the lowest cost of operations per unit output. Low fuel consumption, higher reaches and higher breakout forces with loader bucket of 1.2 cu m and backhoe bucket of 0.26 cu m, Equipment Monitoring System (EMS), fast cycle time are some of the key features of our machines. The structure quality of our BHL is best in class. The structural stability has been proven in various mine applications, be it stone or marble.

What has been the response so far for the EMS?

We have got extremely positive response on EMS from the customers. For many customers, it has resulted in timely intervention of potential savings. For other customers, it has become an integral part of their business through which they can track their machine on a daily/hourly basis even when the machine is at remote location. Customer also has the option of tracking via SMS and also via website.

There are many success stories which are shared by customers wherein major breakdowns are avoided by the use of EMS system in Escorts BHL machines.

From the design perspective what makes your range of BHL more fuel efficient, enhance productivity, and longer lifecycle?

Escorts backhoe loaders has robust structural frame design that results in great stability, performance and serviceability. Large box-section structures in high-stress areas such as the boom nose, foot and cylinder enhance the machine’s durability. The new heavy-duty front axle ensues all wheels remain in contact with the ground even on the roughest terrain, ensuring exceptional stability and reliability. It has a superior working range and reaches deeper than any other backhoe loader in its segment. We also provide choice of two configurations: a standard dipper dig depth 4.8 m and an extendable dig depth 5.9 m.

The syncro shift, reversing shuttle transmission provides four forward and reverse speeds. The hydraulically shifted clutches allow the operator to change direction and travel speed on the go, while the control valves deliver smooth speed and direction shifts, resulting in smooth and accurate operation.

The new tilting engine hood provides excellent access for maintenance. The machine layout has been designed to ensure all daily service points are easily accessible at ground level, for quick and efficient servicing.

Spacious cab has redesigned ergonomics to offer better operator comfort. The large size windows provide outstanding all-round visibility, it improves air ventilation to the operator and it makes easy communication to the back of the machine. All the controls have been specially positioned to offer easy access and faster control. The cabin has a large helper seat along with storage compartments and bottle holder.

Hits: 7211