We can suggest suitable Undercarriage solution to the customer depend on their requirement from our product lineup.

Youichi Takagi, Head Parts Department, Komatsu India

Youichi Takagi, Head – Parts Department,Komatsu India

What types of construction equipment Undercarriage systems do you manufacture for Construction Equipment?

Komatsu has several types of Undercarriages for Hydraulic Excavators and Crawler Dozers in addition to standard type. Our Komatsu customer can choose suitable spec Undercarriage spec depending on the application and requirement.

Few types of Heavy duty type Under carriage: It has very effective for hard application by excellent wear and impact resistance. It is possible by suitable material and heat treatment and unique structure of Bushing system etc.

General construction Undercarriage: In the general construction section, main concern about parts including Undercarriage is the cost.

Therefore, we are preparing General construction Undercarriage for such a customer. The price of this is cheaper than other special spec undercarriage, but it has the suitable performance for light load work like the general construction.

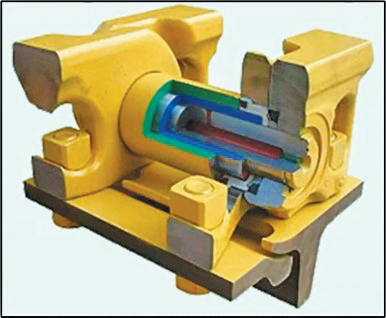

Easy replacement system: Replacement work for undercarriage is very hard, especially for big size machine. And it has the risk by hammering work and pressing work by hydraulic press for removing Master-pin. Mechanic can replace the pin without such a hard work in case of Komatsu developed easy removal pin for undercarriage.

What are the current market trends in construction equipment undercarriage systems in India? How is your company adapting to these trends?

Many competitor’s Undercarriage product are available in the market including local made and import one also.

For that, price competition is very fierce, and competitor’s Undercarriage is cheaper than our product in almost cases. But in based on the life per hour, Komatsu Undercarriage is better than them in many cases, due to high quality and durability. Because we can suggest suitable Undercarriage solution to the customer depend on their requirement from our product lineup. Not only for Undercarriage parts, providing the better cost is our basic policy for genuine parts.

What materials are commonly used in your undercarriage systems? How do you ensure the quality and durability of your undercarriage system?

What materials are commonly used in your undercarriage systems? How do you ensure the quality and durability of your undercarriage system?

We cannot mention about the detail of material because it is confidential. But suitable material and heat treatment are mandatory for Undercarriage parts. Komatsu has a dedicated plant for Undercarriage in overseas.

How does your company invest in research and development to improve undercarriage system performance and efficiency? Have you introduced any innovative features or technologies in your undercarriage systems?

Mainly, development of Undercarriage is done by dedicated design team in Komatsu mother plant in Japan or others. And they are developing the digital solution of Undercarriage system also. For example, digital measuring system by ultrasonic tool are practical in some other country mainly for Mining machinery. Inspection result is utilizing for not only replacement recommendation to the customer but also lifetime data analysis of Undercarriage product.

What kind of after-sales support is provided for your undercarriage systems?

Our distributor is providing free inspection service for undercarriage. Name of the program is Komatsu UC Inspection Service: KUC. It is included to our Extend warranty program MCP (Machine Care Program).

What are the major challenges faced by undercarriage system manufacturers in India? How do you address these challenges?

We are not manufacturing Undercarriage parts in India but now studying about localization of it. Because it is mandatory for cost reducing and meeting to government strategy.

What are your company’s plans for future growth and development in the undercarriage system industry?

We have plans for localization and to introduce digital solution for Undercarriage life management and inspection.

Is there any other important information you would like to share about your company or products?

We have been launched new warranty program for overhauled Engine of our Excavator PC210, PC300/350, PC450 models. If customer ordered Engine overhaul to our distributor, Komatsu gives the 3 years or 6,000 hours warranty to overhauled if it is done by our certified workshop of our distributor. This is very advanced program, and in India, only Komatsu can provide such OEM warranty to distributor overhauled component. Like this, we are providing excellent solutions to our machine even after sold the machine to customer for the maximize their benefit.

Hits: 41