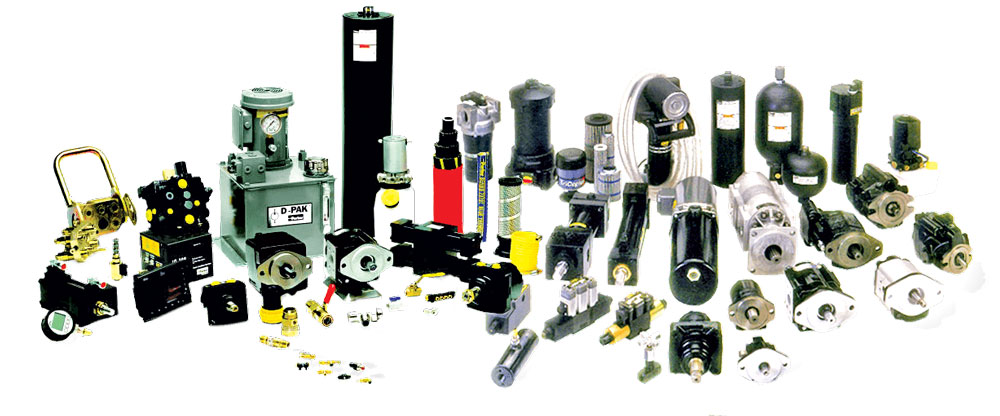

Parker Hannifin has a wide product range suitable for Indian Construction Equipment Market.

Kiran Kagalkar, General Manager – MSDI, Parker Hannifin India Sriram Venkatraman, General Manager – FCDI, Parker Hannifin India Briefly describe your company’s range of hoses & hydraulic components designed for construction equipment. We are India’s leading manufacturer to support Construction

Kiran Kagalkar, General Manager – MSDI, Parker Hannifin India

Sriram Venkatraman, General Manager – FCDI, Parker Hannifin India

Briefly describe your company’s range of hoses & hydraulic components designed for construction equipment.

We are India’s leading manufacturer to support Construction Equipment OEMs with our Hydraulic & Fluid Conveyance products such as Pumps, Valves, Cylinders, Accumulators, Coolers, Braided and Spiral Hoses for their various critical applications.

Do you offer customization options for hoses & hydraulic components?

Parker team is constantly engaged with the customers to understand the application and machine needs and offer customized hydraulic & hose solutions.

How do you ensure the durability and resistance of your products to harsh construction environments?

Hydraulic components are designed for demanding applications to endure harsh environment & give robust performance.

Applications that have rubbing or abrasive surfaces would be supported by our family of abrasion resistance hose with Tough, Super Tough and CP Covers. Our CP cover provides a combination of impact and abrasion resistance making it an excellent choice in any application where the hose is exposed and could be subject to external damage.

Do you provide technical support for selecting the right hoses and hydraulic components for specific construction equipment? How can customers access this support?

Technical Guidelines for the selection of hydraulic components & Hoses is mentioned in our catalogues. Our Parker Website (www.parker.com) provides information on wide range of our products and E-configurators in it allows to customize and describe the attributes of Particular model or series. For further details, you can contact us at sales.india@parker.com where our representatives would get in touch with you to help with your queries. We do Provide customized periodic Seminars / Trainings to Customers on the Proper selection of Fluid motion control & conveyance solutions.

How do you ensure that your hoses are compatible with a wide range of construction equipment?

How do you ensure that your hoses are compatible with a wide range of construction equipment?

We have two state-of-the-art manufacturing facilities at Hyderabad and Nagpur manufacturing products that conform to DIN, EN, SAE , ISO , IS & BS Specifications which will fit to wide range of construction equipment.

How does your after-sales service work in case of product issues or concerns?

We have a product service and repair centre in our Navi Mumbai factory complimented by our wide service network which operates on Pan-India basis.

How do you manage your supply chain to ensure consistent availability of products?

Demand Forecasting: Utilize historical data, market trends, and customer insights to forecast demand for products. This helps to anticipate future needs and planning accordingly.

Supplier Selection: Choose reliable suppliers who can provide consistent quality, lead times, and pricing.

Inventory Management: Maintain an optimal level of inventory to avoid stockouts while minimizing excess inventory costs. Implement inventory tracking systems to monitor stock levels in real-time.

Communication: Maintain open and transparent communication with suppliers. Regular demand forecasts and any changes to requirements to ensure that they can plan their production accordingly.

Risk Management: Identify potential risks in the supply chain, such as disruptions, delays, or quality issues. Have contingency plans in place to address these risks and ensure continuity of supply.

Collaboration: Foster strong relationships with suppliers and collaboration for better responsiveness, flexibility, and the ability to address unexpected challenges together.

Continuous Improvement: Regular assessment of supply chain performance and look for opportunities to optimize processes, reduce costs, and enhance efficiency.

Are there any upcoming innovations or developments in your hoses and hydraulic components that would benefit construction equipment manufacturers?

Are there any upcoming innovations or developments in your hoses and hydraulic components that would benefit construction equipment manufacturers?

With the Construction Market focusing on Better & Smart Control Technologies, we have are offering smart & electronically controlled variable pumps and valves along with sensors and controllers to provide a complete Electro-Hydraulic solution. We are continuously developing new products to meet our customer demands.

With the ever-evolving needs of machinery robustness and compactness which requires the solution with lesser weight and superior flexibility on hoses, we have recently launched PXT Hoses in Tough Cover in India for critical applications for medium-pressure applications which fits its way through tighter routings. With impulse tested up-to 6,50,000 cycles, it is a one stop solution for challenging applications in Tough Environments. There are other internal projects which we are working towards sustainable journey.

Any other information you would like to share with potential customers about your products and services.

Parker Hannifin is actively engaged with OEM’s for Pumps, Valves, Hoses, Tube Fittings etc. & exploring alternate technologies viz. Electrification, Hydrogen, CNG.

Hits: 49