We will continue to invest in internal combustion engines that can provide clean, affordable energy to customers for years to come

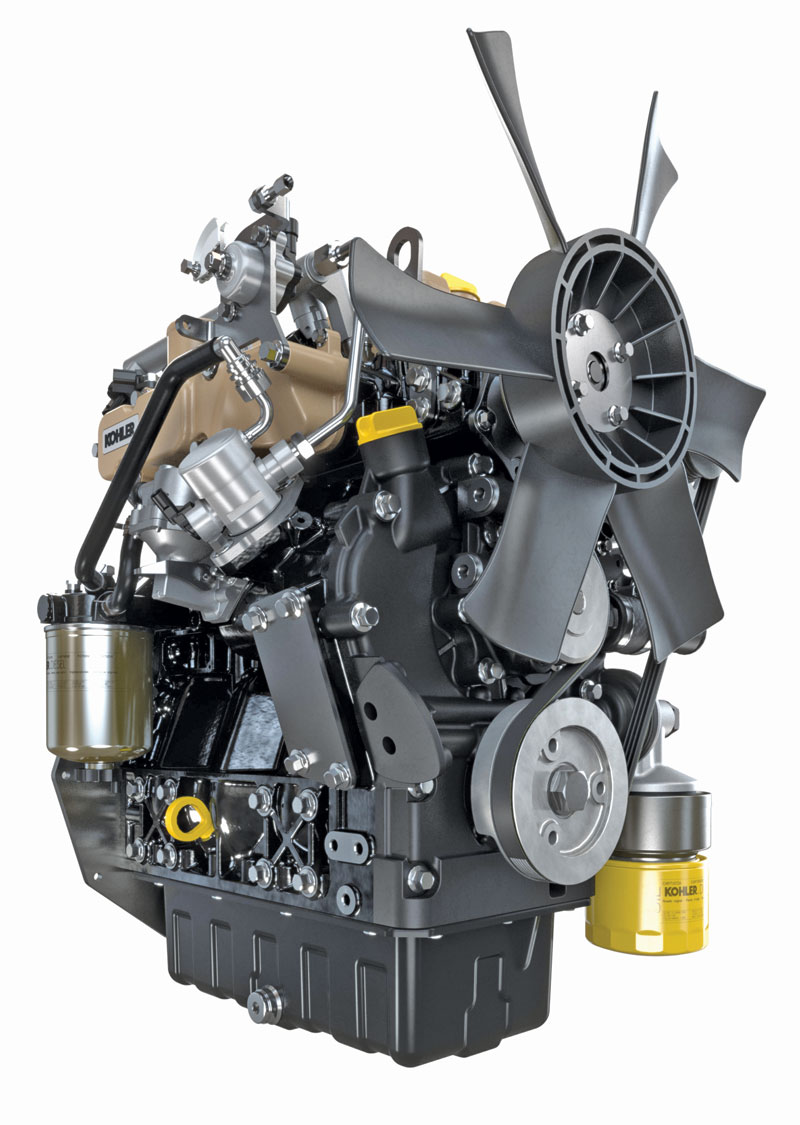

We are participating in the BAUMA show as an exhibitor and will present our range of single-cylinder (6.5 kW KD441), 3-cylinder (18.4 kW KSD Engine), and KDI engines in diesel and small hp gasoline (Petrol) versions.

– ALOK KUMAR

Associate Director, Sales & Service, Kohler Engines

What are your plans for bauma CONEXPO INDIA in terms of product display?

We are participating in the BAUMA show as an exhibitor and will present our range of single-cylinder (6.5 kW KD441), 3-cylinder (18.4 kW KSD Engine), and KDI engines in diesel and small hp gasoline (Petrol) versions.

From your company’s perspective, please offer your views of bauma CONEXPO INDIA as a business generating platform for the CE sector and what do your feel are the strengths of the exhibition?

bauma is one of the most famous trade shows in the world. We attended bauma 2022 in Munich, Germany, in October, and saw an extremely high turnout of customers and suppliers. bauma India is expected to have the same size and status as the one in Munich, and we are quite optimistic that our customers, potential operators, new and emerging companies will attend or visit the show in India as well. Since this is a specialized trade show in the construction equipment sector, those who are intent on growing their business in the CE space will definitely benefit.

How do you look at the current market in India for your range of products?

India’s CE industry totals about $6.5 billion, with more than 92,000 units produced annually and more than 50 OEMs. The Prime Minister recently announced the launch of the national “Gati Shakti” Master Plan. This plan, which amounts to over INR 100,000 crore, focuses on holistic and integrated infrastructure development. It is a significant step by the government toward realizing the vision of making India a $5 trillion economy by 2025. Increased investment in infrastructure will create demand and make growth sustainable, equitable and inclusive. In addition, a comprehensive strategy for road development has been adopted, allowing 100 percent FDI in the road sector. Since roads and other infrastructure are major segments of construction equipment use, this initiative should bode well for the Indian concrete industry. We are equally optimistic about growth opportunities and aim to have an 8-10% market share in the next two years for our engine range especially the single cylinder range and the new KSD engine. India is poised to reach 50 km of road construction per day, so the demand for construction equipment will increase, as will the growth opportunity for our engines.

How have the sales been for the company this year, and given the ongoing and upcoming building and infrastructural opportunities, what are your sales projections for FY23?

Like everyone, we experienced some ups and downs during the pandemic years of 2020, but our sales were generally steady and in 2021 we recovered quickly. The year 2022 also ends positively. For 2023, we expect it to become a breakthrough year because we have launched a new range of engines, KSD – less than 19 KW and compliant with Tier IV / Stage V standards – which will officially go into production at the Indian plant, and will then be destined for the global market.

What are the emerging technological trends in your range of products?

This is a momentous time for the engine industry, a time of transition in which radical changes in the technologies we will have at our disposal in the future are emerging. With the push toward progressive decarbonization and the goal of reducing greenhouse gas emissions, new technologies are projecting themselves ahead of us. We will continue to invest in internal combustion engines that can provide clean, affordable energy to customers for years to come. But among the new pillars of Kohler’s strategy, there are also new avenues to be pursued: alternative fuels, more economical and logistically manageable; electrification and hybridization, to reduce engine size or achieve zero emissions during operation; and hydrogen as a potential green source fuel. Faced with the complexity of this scenario, Kohler responds with different solutions needed to meet the requirements of a wide range of machines.

Then, the increased use of automation, IOT technology, cloud communication, etc. will also definitely be part of the future of our product.

What are your investments made in the Indian market in terms of manufacturing facility, distribution network and other aspects?

We are investing significantly in our current plant in Aurangabad, which was recently expanded to create the new production line for the KSD, the new sub-19 kW engine range.

We are also expansion for the KDI engine, which will be 35 kW and can be further expanded to the 105 kW Stage V engine.

How do you access the future potential for your products in the Indian market?

The future is bright, and the potential of our engines is very high. Every OEM, whether local, glocal, or global, wants to have an engine that meets all globally applicable environmental and emission standards, is highly fuel efficient, compact, reliable, and safe, has the best power and torque density, and, finally, offers the best operating cost.

Hits: 1