We will be showcasing a comprehensive range of products tailored to meet the specific demands of mining sector.

Sanjeev Taparia, Chief Sales & Marketing Officer, NBC Bearings What specific goals and priorities are you aiming to achieve during IME 2023? During IME 2023, our goals and priorities are aligned with our commitment to serving the mining sector effectively.

Sanjeev Taparia, Chief Sales & Marketing Officer, NBC Bearings

What specific goals and priorities are you aiming to achieve during IME 2023?

During IME 2023, our goals and priorities are aligned with our commitment to serving the mining sector effectively. We aim to highlight our range of bearings and solutions tailored to the unique demands of the mining industry. This includes bearings designed to withstand heavy loads, shock loads, and the harsh environmental conditions commonly found in mining operations.

IME also provides an excellent platform to connect with industry leaders, mining professionals, and potential clients. Our priority is to establish and strengthen relationships, fostering trust and collaboration within the mining sector. Sustainability is a growing concern in the mining industry. We aim to showcase our sustainable bearing solutions and environmental initiatives. This includes discussing how our products can contribute to reduced energy consumption and improved operational efficiency, aligning with broader industry sustainability goals.

Can you provide insights into the range of products you intend to showcase at IME 2023?

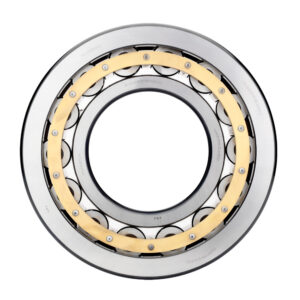

NBC Bearings will be showcasing a comprehensive range of products tailored to meet the specific demands of the mining sector. These products are designed to enhance the performance and reliability of machinery and equipment used in mining operations. These include Spherical Roller Bearings which are known for their ability to accommodate heavy radial loads and axial loads in both directions. These bearings are essential in the mining industry for applications involving heavy machinery, crushers, and conveyors. They offer exceptional durability and resistance to harsh environmental conditions.

Similarly, Tapered roller bearings are commonly used in mining equipment such as trucks, excavators, and loaders. NBC Bearings also offers a range of pillow block bearings and specialised bearings.

In addition to our range of bearings, we will showcase our condition monitoring solutions. These technologies help mining operators track the health of their equipment, predict maintenance needs, and prevent costly downtime. This includes the use of smart sensorized bearings that can provide real-time data on bearing condition.

What is your perspective on the anticipated market dynamics in your sector?

We operate in automotive, railways, industrial applications, and, more recently, aerospace and electric vehicles.

In automotive sector, the shift towards EVs and HEVs is gaining momentum. As a bearing manufacturer, we see a growing demand for specialized bearings that can meet the unique requirements of electric powertrains. Also, the drive toward lightweighting necessitates bearings that are not only strong but also lightweight. We expect an increased demand for such bearings.

In the railway sector, high speed trains will require advanced railway bearings that can withstand high speeds, heavy loads, and extended service intervals. We are also collaborating beyond bearings to supply complementary products to Indian Railways.

In the broader industrial segment, we anticipate that bearings integrated with sensors and smart technologies will be essential for industrial equipment to operate efficiently and predictively. Industries have diverse needs, and customized bearings designed for specific applications will be in demand. Manufacturers that can offer tailor-made solutions will have a competitive edge.

Could you elaborate on your company’s initiatives and progress in creating eco-friendly products?

NBC Bearings is dedicated to developing and manufacturing eco-friendly products that contribute to sustainability and reduce the environmental impact of our bearings.

We have invested in research and development to identify and implement materials that are more environmentally friendly. This includes the use of materials with lower environmental footprints, reduced emissions during production, and materials that are easier to recycle.

We have implemented energy-efficient manufacturing processes in our facilities. This not only reduces our carbon footprint but also results in more energy-efficient bearings. By optimizing our manufacturing techniques, we can produce bearings that are more durable, require less maintenance, and operate at peak efficiency, thereby reducing the energy consumption of the machinery in which they are used.

Condition-based monitoring is an integral part of our efforts to create eco-friendly products. By equipping our bearings with smart sensors, we enable customers to monitor the condition of their equipment in real-time. This not only reduces unplanned downtime but also optimizes maintenance schedules, ensuring that bearings are replaced or serviced only when necessary. This approach minimizes unnecessary waste and resource consumption.

NBC Bearings is actively exploring recycling and circular economy initiatives. We are committed to designing bearings that are easier to disassemble and recycle. We also provide remanufacturing services as part of our offerings to enable re-use of bearings.

What obstacles and difficulties do you perceive within the sector currently?

In the sectors where NBC Bearings operates, there are several challenges that we forsee.

- The ongoing global supply chain disruptions affected the timely delivery of critical components and materials required for bearing manufacturing. These disruptions can lead to delays in production and affect our ability to meet customer demand.

- Increasingly stringent environmental regulations and standards require manufacturers to invest in eco-friendly practices and materials. While this is a positive step for sustainability, it can also lead to increased compliance costs and complexities.

- The rapid evolution of technology and digitalization in various sectors, including Industry 4.0, has created a need for bearings that can operate in more complex and data-intensive environments. Meeting these evolving technology requirements can be challenging.

- The bearing industry is highly competitive, with many manufacturers vying for market share. Maintaining a competitive edge requires continuous innovation and a strong commitment to quality.

- The proliferation of counterfeit and spurious bearings in the market poses a significant challenge. These substandard bearings can lead to equipment failures and safety hazards, damaging the reputation of genuine bearing manufacturers.

- The import of low-cost Chinese bearings can create pricing pressures in the market. While cost-effective, these imports may not always meet the quality and safety standards upheld by established bearing manufacturers.

In conclusion, while there are significant opportunities in the sectors where NBC Bearings operates, there are also notable challenges. NBC Bearings is committed to overcoming these obstacles through innovation, quality, sustainability initiatives, and strong customer relationships, all of which are crucial in addressing the complexities of the sectors we serve.

Hits: 45