Rossi has almost all the product types in the basket, and we have millions of permutations and combinations.

Hemant Mohindra, Managing Director, Rossi Gearmotors India What types of construction equipment are your geared motors primarily used in? Geared motors are primarily used by Overhead travelling cranes, tower cranes, excavators, concrete mixers, pavers, trenchers, concrete pumps arial and boom

Hemant Mohindra, Managing Director, Rossi Gearmotors India

What types of construction equipment are your geared motors primarily used in?

Geared motors are primarily used by Overhead travelling cranes, tower cranes, excavators, concrete mixers, pavers, trenchers, concrete pumps arial and boom lifts, man and material handling lifts, etc.

What are the different torque capacities available for your geared motors?

Rossi has one of the widest range of gearboxes and gear motors. The torque range is between 32 NM to 3 mn NM.

What materials are used in the construction of your geared motors to ensure durability and reliability in harsh construction environments?

Rossi doesn’t compromise in any way to reduce the product cost, as the cost of ownership is basically determined by the service life of the units and not by the initial purchase price.

Rossi manufactures only Cast-Iron units as this gives better rigidity and service life. We use highest quality of materials for casing (up to GG 40) and gear materials are equal to or better than the industry standards.

What is the expected lifespan of your geared motors under typical construction equipment usage?

What is the expected lifespan of your geared motors under typical construction equipment usage?

We are asked this question many times and in-fact, we get surprised by this question. The life span of a gear unit depends mainly upon the product selection, loads, application and oil change frequency. Our units don’t need to be opened to check the internal condition. If the user keeps changing the oil as per recommended frequency, the gear units run for a very long time. Still if we have to give a number, it could be minimum 10 years.

Are there any special features or technologies incorporated in your geared motors to enhance their reliability and performance?

Are there any special features or technologies incorporated in your geared motors to enhance their reliability and performance?

The products don’t need any special features of technologies to give a long and trouble-free service life. The only mantra is correct product selection based on the application, which our team is expert in doing.

What maintenance procedures are recommended for your geared motors to ensure their optimal performance?

Rossi firmly believes in the philosophy that in a well-engineered product, the owner shouldn’t have to worry about preventive maintenance. However, it’s not easy to prove it without demonstration. In our products, there is no maintenance required except oil change at recommended frequency. Our gear products don’t need periodic inspections by opening inspection covers. Our product selections are 100% compliant to load requirements application specification. This plays a big role in the service life of products. We have come across cases where the gear drives have been running for 20-25 years, without any problems. This speaks very high about the level of engineering that our products have gone through while designing.

Do you offer customization options for your geared motors to meet specific construction equipment requirements?

Do you offer customization options for your geared motors to meet specific construction equipment requirements?

Rossi has almost all the product types in the basket, and we have millions of permutations and combinations. This makes us one of the widest product companies in the world. Due to this fact, we don’t deal in the fully customized products. However, we have so many options in the product selection that there could be very few applications which we can’t serve. This almost eliminates the need of making custom products. This statement is backed up by the fact that less than 1% enquiries that come to us are for the customized units.

How are your geared motors designed to be environmentally friendly and comply with relevant emissions regulations?

What makes a geared motor environment friendly is mainly its efficiency. We make the products that are of highest efficiencies. We also reduce the impact on the environment by adoption of eco-friendly paints. Moreover, the carbon footprint of our products is lesser as we have one of the highest power-to-weight ratios in the world. This means, our products, despite having shorter footprint or overall dimension, deliver higher torque output which means, lesser carbon emissions and lesser energy consumption to manufacture our products.

How do customers access after-sales support and service for your geared motors?

How do customers access after-sales support and service for your geared motors?

First of all, after sales support needs from our customers are minimal. Our warranty cost is less than 0.1% which means that the product quality and selection is without any compromise. However, there could be some specific customer needs where they need support. This could be commission support, some spare parts need, etc. For this, they get the information from our website. Apart from this, we have dealers and service team spread across India who help the customers in their service and spares needs.

Are there any upcoming advancements or innovations in your geared motor technology that might benefit the construction equipment industry?

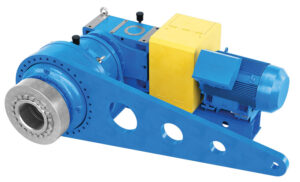

Rossi is entering into new business through new products launches that includes new series of coaxial gear drives (iFit series) and Variable frequency drives. Apart from this, we have lot of accessories as options that suit all construction equipment applications. These include vibration sensors, thermal sensors, desiccant breathers, tachometer, fluid couplings, pumps, cooling systems, etc.

Hits: 8