Improving Performance & Assuring Flexibility to Crane Manufacturers with latest Hoist Gear Motors from Bonfiglioli

Hoist in Cranes – Application & Need Be it any Greenfield or Brownfield Expansion, Cranes are the first equipment to get commissioned. From MSME to Large Scale Industries, Overhead EOT Cranes are preferred choice in all Material lifting application. Safety

Hoist in Cranes – Application & Need

Be it any Greenfield or Brownfield Expansion, Cranes are the first equipment to get commissioned. From MSME to Large Scale Industries, Overhead EOT Cranes are preferred choice in all Material lifting application.

Safety along with Performance is the highest priority today across the Crane industry. Geared motors are most important element when it comes to ensuring reliability in Crane Operations. Overhead / EOT crane manufacturers are continuously in search for superior solutions that can integrate gearbox and electric motor within their modern compact hoists that are not possible with existing low-cost solutions. Bonfiglioli has launched their HF (Hoist Series Gearmotors) that incorporate all the requirements of EOT manufacturers in 3T to 12T hoisting capacity with ISO mechanism class M7

Gear motors are the heart of any hoisting systems & if optimally selected they perform safely & help customer conserve operational time & cost. An incorrect selection often leads to unplanned maintenance, safety hazards and higher operating costs.

Bonfiglioli’s HF series Gearmotors for hoisting application offers several features that helps hoist designers to make optimized selection. The latest advancements in gear technology helped Bonfiglioli to manufacture the gear motor with the highest power density that offers dual benefits to the customer. i.e. Supporting higher loads and being compact at the same time. The compact Size of HF combined with safety and reliability makes it the preferred choice for OEMs & End-users performing assembly, operating & carrying out maintenance tasks.

Bonfiglioli’s HF series Gearmotors for hoisting application offers several features that helps hoist designers to make optimized selection. The latest advancements in gear technology helped Bonfiglioli to manufacture the gear motor with the highest power density that offers dual benefits to the customer. i.e. Supporting higher loads and being compact at the same time. The compact Size of HF combined with safety and reliability makes it the preferred choice for OEMs & End-users performing assembly, operating & carrying out maintenance tasks.

- Safe & Reliable operation

Gearbox and Brake Motor are the most crucial components that ensure the safe operation of the overall crane. Gear motors help users to lift the loads safely & their design can highly influence the performance and reliability of the overall crane.

Safety is guaranteed through Gear Profiles designed for high Power density. Bonfiglioli’s HF series also include optional External braking which increases safety thereby providing peace of mind to users.

The investments are high when it comes to purchasing a crane or hoist. For this reason, Engineers design cranes and hoists to meet accurate duty service classifications. Greater a crane’s operating time, higher is its duty cycle and more chances to experience wear & unexpected maintenance if not properly sized. One of the core design philosophies incorporated into Bonfiglioli’s HF Series is strict adherence to the FEM/ ISO mechanism class. Customers can select each model according to their workload from M5-M7 for all 4/1 Fall Configuration. Although a Crane may be manufactured in one part of the world, most OEMs assemble it in a region & supply to locations far from their base location. Thus, it is critical that Gear motors for Cranes have global approval, since Bonfiglioli HF series is designed as per FEM/ISO it can be seamlessly used for a variety of applications anywhere in the world. Thanks to Bonfiglioli’s strong Direct & Indirect Network spread across 80 countries local support would be easily available for spare parts supply.

Brake Motors

Crane & Hoist industry is a sector where Customers selects Brake Motors as default. The IEC Brake motors offered by Bonfiglioli have high braking torque of 2x times of Motor Torque for instant stopping and are easy to install and operate. Brake motors are designed for Intermittent Duties S4-60% CDF and up to 150 starts/hr. The brake can be connected to the non-drive end of the motor as per customer preference. Manual release lever is provided on non-drive end and the position is customizable. Motors are VPI treated to be compatible with VFD operation as it is important in Hoist Application.

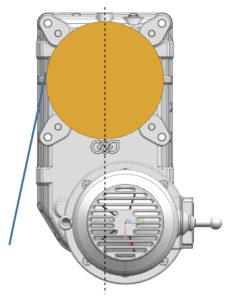

External Brake

External brakes that are provided on the Motor shaft acts as standalone brake other than Integrated Brake Motor. This is specifically prefered in the industry as accessibility of brakes in Brake Motor are

limited in Single Girder EOTs & directly affects uptime. Customers can measure brake pad thickness without removing the motor fan cover as the External Brakes are easily accesible from outside which significantly reduces the maintence time taken.

2 Flexibility

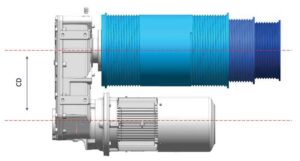

A. Higher Center & Offset Distance

Crane manufacturers use various drum diameters to get their desired Lifting speed and decide the tonnage. When they don’t have sufficient Center distance there are limited to select only one size which results in one lifting speed. The HF Series developed by Bonfiglioli understood this bottleneck and increased the Center distance to accommodate 3 different drum sizes. This gives liberty to Crane manufacturers to choose optimum drum size considering load and lift speed. Additionally, the increased Center Distance (CD) gives sufficient space to perform maintenance work. Increased Center Distance allows Hoist to configure various Frame Sizes of IEC motors as per their load without any interference with Drum.

When Gearbox and Motor are at the same center axis there lies a risk of wire rope rubbing with the motor while lifting the loads which creates an unsafe condition. HF series from Bonfiglioli addressed this challenge by providing offset between motor and gearbox axis which completely evades the above-said issue. The increased space gives sufficient space for the rope guides to pass as the drum rotates.

The traditional Parallel shaft gear motors available in the market does not include these two critical features. In addition to increasing CD & Offset, various ratios & IEC Motor option available also help customers to optimize their hoist design depending on load.

B. Mounting & Connections

Safety is Integral part of the whole crane & Gearbox-Drum connection is one of them. This is essential in maintaining uptime and enhancing the safety and reliability of the Cranes. Without the right connection hoist may not function properly, causing industrial process to halt production. Bonfiglioli offers 3 different types of Connections for Customers to choose depending on their need. Splined connections along with Flanges are generally preferred in the Industry and HF Series comes with this included in standard Package.

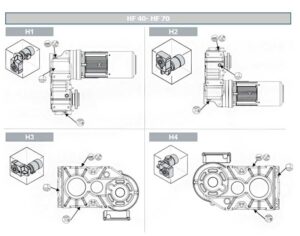

HF Series can be installed & operated in 4 mounting positions for which provisions are provided. Bonfiglioli included such features to help Customer Balance the Hoist design depending on Single & Double girder Structures.

Connection options

1. Solid Output Connection

2. Splined Connection

3. Output with coupling connection

Testing the Performance leads to Greater safety and Greater reliability

Crane Gearmotor must undergo highly rigorous testing to last hundreds of hours. This is essential in hoisting applications that are subject to braking, various operating cycles in real time working conditions. When operating Cranes in Industrial environments the primary objective behind every operator is to handle the load safely. It’s critical to know which are the features and capabilities to look for in safety. Bonfiglioli conducted rigorous tests on HF Series to ensure Gearmotor meet exact operating criteria, ensure reliable performance and achieve compliance. The tests are carried out to validate Durability of Gears, Efficiency of lubrication, and reliability of Bearing & motors with various loading patterns as per real time working conditions.

3. Availability

3. Availability

Lastly, for Crane & Hoist Manufacturers delivery schedules are extremely critical and they consider lead-time while selecting Gearmotor. No one likes to hold up an entire project or keep a system shut down waiting for a Gearmotor. Bonfiglioli is the only Gearmotor supplier who manufactures hoist specific Gearmotor in India at its facilities in Chennai & Pune. With the Local manufacturing Bonfiglioli can ensure fastest delivery times for all standard configurations.

The newly commissioned machine dedicated for Hoist Gearmotor can complete assembly under 90 minutes that assures of faster and reliable delivery. Bonfiglioli with its presence for last 24 years has established nation-wide sales and service network spanning to almost every part of the country that helps us to serve our customers faster & better. Bonfiglioli’s HF series is the right product for customers looking to have Hoist Specific Gearmotor made in India with Global quality.

Hits: 522