PROTECTING THE SYSTEM…

Construction machinery filters protect the system components from the damage caused due to contamination. The work of each type of filter used in construction machinery is to enable flows and catch impurities such as dust (contaminants in the air), impurities

Construction machinery filters protect the system components from the damage caused due to contamination. The work of each type of filter used in construction machinery is to enable flows and catch impurities such as dust (contaminants in the air), impurities in the fuel. Expanding construction activities in various parts of the world coupled with increasing investment in infrastructure is expected to drive the growth of the market. Equipment Times looks into the growth of filter market, technological trends and challenges in the filter’s segment.

Growing road construction

The growth of the market is attributed due to the increasing road and paving construction which uses heavy machinery. The use of construction machinery filter reduces the maintenance costs, therefore a significant increase in the efficiency of construction machinery for road construction across the various developing economies due to the fact the heavy investments are being done in countries such as China, India, and Indonesia for the construction of highly advanced and durable road transport networks. In addition, the development of rural areas has led to the construction of new roads and highways networks for the connection of rural and urban communities.

High investment in infrastructure across countries

Growing infrastructure investment across countries is expected to boost the demand for Structural Health Monitoring (SHM) systems due to the benefits they add pertaining to the sustainability of structures and low cost in maintenance and inspection after being built. Emphasis on superior infrastructure is a key policy factor in both the developing and the developed world as a robust infrastructure forms the base for overall economic growth and high productivity in public as well as private sectors. Be it the building of bridges, dams, buildings, stadiums, flyovers, railway stations, and shopping malls, or be it applications such as diagnosing vessels and platforms in marine industries, aircraft frames in aerospace and defense, and inspection of large machines, heavy investments are being made in all the above, hence, likely to give a push to the adoption of premium quality construction machines filters at an even larger scale.

Air Filters

Heavy construction equipment and the human body might seem incredibly different, but they have one thing in common. If they can’t breathe, they can’t function and will eventually fail. While equipment doesn’t have a pair of lungs like you’d find in your own chest, if a machine’s intake gets clogged, it will eventually stop working.

Air filters protect the delicate inner workings of internal combustion engines from dust, dirt and other debris you might encounter on the job site. Part of their job is to get clogged, and when they do, they require cleaning or replacement.

Clean air filters do more than protect your engine’s inner workings. They also improve fuel economy and decrease engine stress. These abilities improve functionality and productivity and can even increase the device’s life span.

A large piece of equipment burns 3-5 gallons of extra fuel every hour with a 50%-75% clogged air filter. Over the course of a 12-hour shift, that’s an extra 60 gallons of fuel. If you’re paying $4 or more for diesel fuel, the costs can add up quickly.

Fluid Filters

Air filters have a single task — filtering the air that moves through the engine. However, that isn’t the only thing that needs filtering. Fluid filters come in all shapes and sizes for each type of fluid.

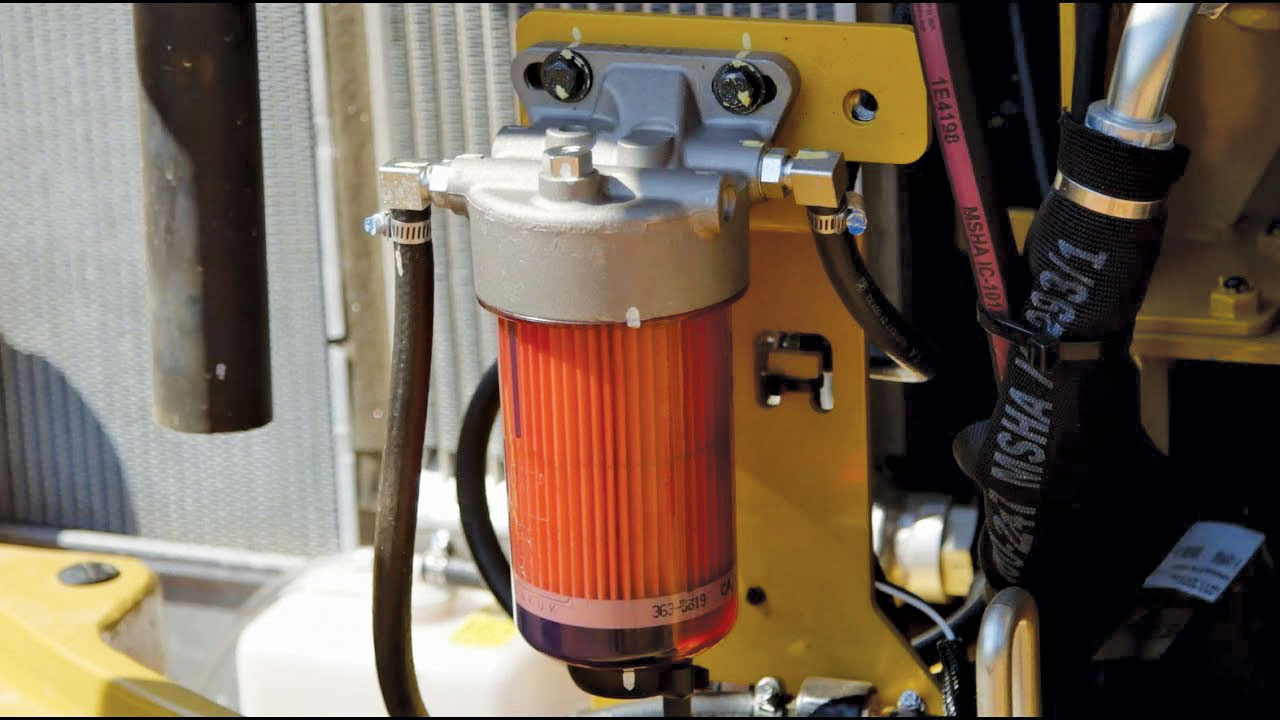

Fuel Filters

The massive tanks that store gasoline and diesel fuel aren’t perfectly clean. Dirt, debris and rust build up in the tank and get stirred up each time a tanker truck arrives to refill it. Those contaminants can end up in your tanks, and without the aid of a fuel filter, can clog up the fuel system as well.

Oil Filters

Oil filters remove contaminants from the oil that can damage the engine’s inner workings. Without the filter, this debris can wear away the engine’s interior over time, compromising its compression and power.

Miscellaneous Filters

While not common on most types of heavy construction equipment, high-pressure oxygen systems require filters to prevent fires in vital components since oxygen can be highly combustible.

Transmission Filters

Equipment with automatic transmissions comes with transmission filters to remove any dirt and debris from the system that could damage the transmission’s delicate gears. Equipment with manual transmissions doesn’t have or need filters.

Coolant Filters

While not common on automobiles, coolant filters that prevent clogs and potential damages to the cooling system are frequently found on heavy equipment.

Opportunities: Advancements in filter media/technology

A filter media is the core component of a filter. It is used to capture any unwanted and foreign particles. It is majorly made up of cellulose, synthetic, glass fiber, and activated carbon, depending on the applications. Advancements in filter media types or technology will offer a huge opportunity for automotive filter manufacturers in the coming years. Currently, cabin filters are offered to resist dust particles entering the vehicle. Most dust filters stop 100% of all particles that are 3 microns or larger and 95–99% of particles that are 1–3 microns in size. However, in the coming years, there would be a mass market for dust and odor filters. The blend of dust and odor filters has a coating of activated charcoal or baking soda to absorb odor and air pollutants.

Nowadays, most of the vehicles’ air intake filters are made up of cellulose media, which is very cost-effective. However, synthetic media types are gaining popularity and would have a decent market share in the future, mainly due to their various advantages over the cellulose media. For instance, synthetic media types offer increased flow area, provide high performance, and are less sensitive to water. These filters can be used to allow better airflow for combustion, resulting in higher fuel efficacy and lower emission.

Hits: 47