MANN+HUMMEL Digital Filter Suite: Intelligent Filter monitoring for higher performance and lower costs

Avoiding the high costs of downtime is key to success in fleet operations. Today, automation drives many processes and operations which are not manageable without the help of algorithms. MANN+HUMMEL has developed a smart solution for filter monitoring. The Digital

Avoiding the high costs of downtime is key to success in fleet operations. Today, automation drives many processes and operations which are not manageable without the help of algorithms. MANN+HUMMEL has developed a smart solution for filter monitoring. The Digital Filter Suite maximizes filter performance and makes maintenance more efficient and effective for fleet operators of agricultural and construction machines, heavy engines and commercial vehicles – in a fully automated, precise and reliable way. The result? Reduced downtime and lower costs which can lead to higher performance and greater success.

What is a Digital Filter Suite for filter monitoring?

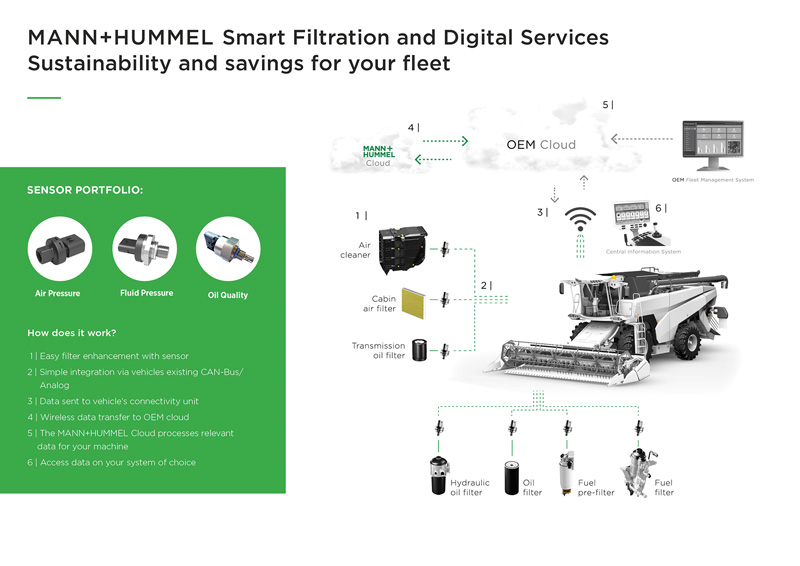

The MANN+HUMMEL Digital Filter Suite is a key component that can be easily integrated into telematics systems for construction vehicles, industrial motors or in agricultural machinery. It allows global players, medium-sized companies and smaller businesses to monitor air and fluid filters, as well as air and fluid quality, effortlessly – everywhere and at any time. Combining the power of state-of-the-art software solutions with intelligent filter sensors, the system ensures your operations run smoothly and cost-effectively. The MANN+HUMMEL Digital Suite is available for various industrial, transportation and automotive filters including: fuel, hydraulic oil, cabin air, engine air , as well as, transmission and engine oil filters

How does the Digital Filter Suite simplify filter monitoring?

When talking about filter performance and filter maintenance in the OEM context, it’s about effective machine and fleet monitoring. It’s about protecting people. And it’s also about cost control and long-term solutions that are easy to integrate. In short, it’s a highly complex challenge for OEMs. The Digital Filter Suite employs sensors in filter systems or additional components only where it makes sense. This reduces unnecessary data noise. These carefully deployed sensors measure the filter status in real time and monitor their performance. The data collected, then uploaded, from vehicles or machines equipped with our Smart Filtration Solutions to the respective OEM’s Cloud. There, it’s anonymized and passed on to the MANN+HUMMEL Cloud. Our filter algorithms then analyze the transmitted data and generate precise information for smart predictive maintenance. These insights are sent back to the OEM, who can make them available to customers, operators and other users via app or in the telematics system.

What are the benefits of Smart Filtration Solutions from MANN+HUMMEL?

Networking hardware and software offers technical buyers, engineers and project managers many advantages that they can pass on to their customers and users. Operation behavior and use-case information, identification of over or under specialized filtration, insight into warranty claims, to name just a few.

Cutting costs through filter monitoring

Cutting costs through filter monitoring

Filter monitoring of machines, fleets and individual vehicles reduces unnecessary maintenance costs thanks to dynamically calculated service intervals. Powerful tools, such as our RUL algorithm (Remaining Useful Life) for filter life prediction, monitor equipment operation and environmental conditions to continuously calculate the maximum time that a filter can safely and effectively protect a system without compromising performance. Thanks to automated algorithms and sensor-assisted monitoring of air, fluid and filter quality, customers can prevent machine downtimes and avoid vehicle damage or engine failures that would have gone unnoticed. Monitoring filter status and fleet performance in real time enables accurate industrial predictive maintenance like never before.

Smart filtration thanks to smart monitoring

Smart filtration thanks to smart monitoring

Whether it’s operational status, system alerts, engine operating hours, estimated service dates and more, our Digital Filter Suite instantly displays details about any vehicle or machine on demand. Real-time analytics help identify actions to optimize machine and filter efficiency which improves industrial performance overall. For example, digital filter monitoring can ensure optimal differential pressure measurement in heavily used ventilation systems. The Digital Filter Suite also enables real-time monitoring of air quality in vehicle cabins and machine environments. So you can protect your employees’ health. All vehicle, machine and filter data is stored centrally and securely in the cloud. For fast access to all data, more flexibility and intelligent filtration solutions that are constantly learning.

Hits: 21