Better Bandwidth Utilization

B&R bus controller overcomes CAN topology restrictions. The new POWERLINK bus controller X67BC8780.L12 from B&R has an integrated hub for eight CAN connections. The star topology of the CAN network allows a higher maximum total cable length and better utilization

B&R bus controller overcomes CAN topology restrictions.

The new POWERLINK bus controller X67BC8780.L12 from B&R has an integrated hub for eight CAN connections. The star topology of the CAN network allows a higher maximum total cable length and better utilization of the bandwidth. It also greatly simplifies cabling.

External CAN devices can be connected to each of the eight separate CAN lines with a standard CAN bus topology. Each line can extend out to the maximum length determined by the baud rate. All eight CAN bus controller connections are terminated using integrated terminating resistors. Full FPGA implementation allows the hub to achieve minimal throughput times. The device offers IP67 protection and is suitable for installation outside the control cabinet.

Hub Optimizes CAN network

According to its specifications, a CAN network can only be built as a line structure with very limited branch lines. The new X67 hub groups various CAN segments into a collision domain. It functions similarly to an active star coupler in a fiber optic network. With the active coupling, the individual segments are no longer subject to the restrictions of branch lines, which greatly simplifies cabling.

Integrated Sensor Power Supply

At each CAN connection, 200 mA are available for the sensor power supply. The connections are short-circuit proof. The bus controller has a wide voltage range of 9 to 32 VDC. All sensors used in the industrial and automotive sectors can be connected directly using a single cable. An additional connector allows the I/O power supply to be daisy-chained to additional modules. The M12 connection technology and use of prefabricated standard cables, commissioning teams can immediately begin setting up the machine without having to first tediously check cables.

Clear Display of Online Parameters

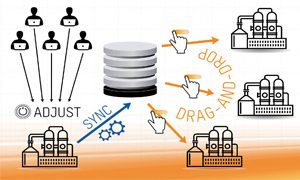

Convenient online parameter management for process control technology.

The new version R4.2 of the APROL automation platform provides a powerful and convenient system for managing online parameters. APROL DisplayCenter displays a clear overview of online parameters and facilitates the commissioning of measurement and control loops. Online parameters can be dragged and dropped to other systems.

Different views allow a clear display and uncomplicated modification of the online parameters. The faceplate view offers a well-structured user interface. The system logic is displayed in the control module view. Parameters can be entered and control modules can be enabled in the list view. Depending on the requirements, the appropriate view can be selected or you can switch between the views.

Transfer Parameters

The new operating dialog boxes not only provide a better overview of the parameters, but also allow existing online parameters to be transferred to other measuring points. To ensure seamless traceability, when online parameters are fed back into the APROL project engineering tool CaeManager, a new version is automatically created with the comment “Online parameters imported”.

Hits: 71